How Many Containers? An In-Depth Guide To Ship Sizes

No single invention has revolutionised modern shipping as much as the introduction of the shipping container. Since the first purpose-built container ship was introduced in the 1950s, container ships have gained massive popularity in the industry for their ease of use, reliability, and cargo protection.

Container ships have now grown in size so much that some ships can transport over 24,000 containers. But just how big is a shipping container, and how much can you fit in one?

How big is a shipping container?

The capacity of a container ship is defined by how many twenty-foot containers, or ‘Twenty-Foot Equivalent Units’ (TEU), it can carry.

A standard shipping container is 20 feet long, 8 feet wide, and 8.5 feet high. This means that a 20-foot shipping container has internal dimensions of 1165ft3, or 33m3. Of this space, around 28m3 is usable for storage.

You may find it difficult to picture how much space that is, or what you could fit into it. Here are some examples of how much a single TEU could hold:

- 26 three-seater sofas

- 200 full sized mattresses

- 48,000 bananas

- 400 flatscreen TVs

- 50 refrigerators

40-foot shipping containers are also widely used. They provide twice as much storage space as a 20-foot container but are most commonly used for large volumes of low-weight cargo.

The amount you can fit in one shipping container is a matter of weight as well as volume. The maximum amount of weight that can be loaded into a 20-foot shipping container is an impressive 23 tonnes.

However, although a 40-foot shipping container provides much more internal cargo space, its maximum weight limit is 26 tonnes in order to preserve the structural integrity of the container.

Other sizes and shapes of shipping container do exist, such as the ‘40HC’ container, which is a taller version of the 40-foot container, but the vast majority of containers used worldwide are of the standard 20 and 40 foot design.

The beauty of shipping containers is that almost every shipping container in the world is built to ISO 668 specification, which standardises their sizes, measurements, and weight.

This means that you could buy a 20-foot container in Mexico and another in India, and they would be of identical dimensions. This has been key to the shipping container’s success.

Container ships – getting bigger all the time?

There are 8 major categories of container ship. The nomenclature of ship sizes has traditionally been based on which parts of the world they can sail through, and the capacities below are estimates as the actual size category of a ship typically depends on the physical size of the ship rather than its carrying capacity.

Panamax, for example, is the largest size of container ship which can fit through the old Panama Canal locks. New Panamax is the name given to the largest ships which can fit through the new Panama Canal locks.

| Size category | Capacity in TEU |

|---|---|

| Small Feeder | <1,000 |

| Feeder | 1,000 – 2,000 |

| Feedermax | 2,000 – 3,000 |

| Panamax | 3,000 – 5,100 |

| Post-Panamax | 5,100 – 10,000 |

| New Panamax | 10,000 – 14,500 |

| Ultra-Large | 14,500 – 21,000 |

| MGX-24 | >21,000 |

Smaller ships, up to the size of Feedermax, may be equipped with their own onboard cranes for loading and discharging containers. This is because they may visit smaller ports that do not have the necessary cranes and equipment, so the ships must do it themselves. These types of ships are known as lift on, lift off or LILO ships.

The main trade of feeder ships is to transport containers from smaller ports to larger ‘hub’ ports, where the containers will then be loaded onto a larger container ship for mass transport to a final destination.

The largest category of ships, Megamax-24, or MGX-24, is reserved for the largest container ships which can take 24 rows of containers, with 24 containers in each row.

When were container ships invented?

The invention of the standardised shipping container is credited to American businessman Malcolm McLean, who owned a trucking company.

McLean saw the inefficiency of loading and unloading break bulk cargo and sought a solution. As a result, he not only created the first iteration of the shipping container, but also built the first purpose-built container ship to carry them in 1956, called Ideal-X.

The Ideal-X was able to carry containers in a single layer on top of her cargo hold, and was seen much as a prototype. The vessel that followed her in 1957, named Gateway City, was the first true container ship in that she was capable of carrying containers stacked on top of one another.

Due to the reduced manpower required to load a shipping container compared to break bulk, McLean’s invention saw his cargo loading costs fall from $5.86 per ton to $0.16 per ton, a 36-fold saving. This also allowed ships to spend far less time in port, meaning that they could carry out more voyages and make more money.

If you’d like to learn more about the difference between container ships and other types of cargo ship, check out our article: Cargo Ships vs Container Ships: What’s The Difference?

The evolution of the ultra-large container ship

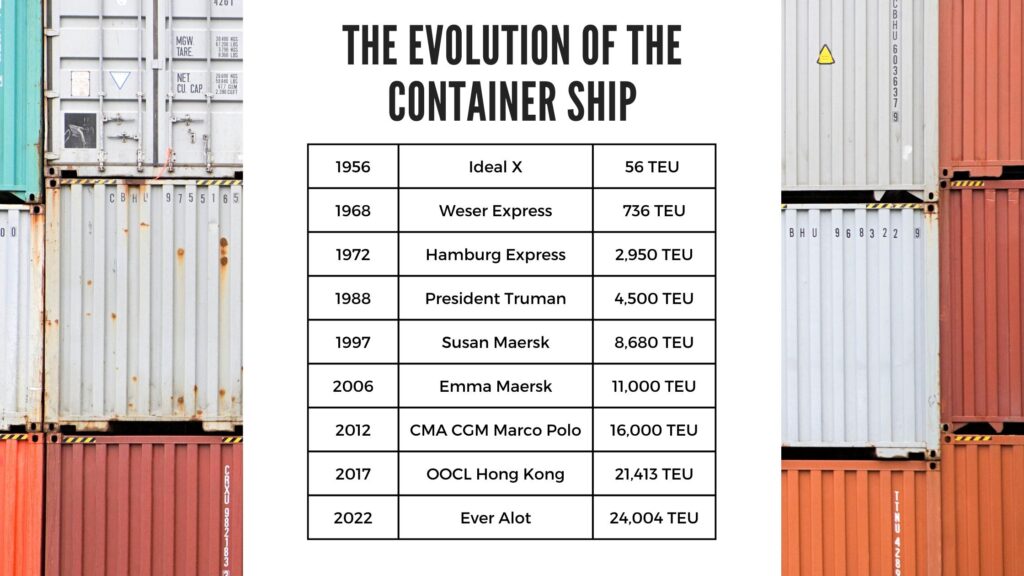

It is easy to see how the size of container ships has increased over time. Container ship sizes have doubled every ten to fifteen years since the late 1960s, with the rate of growth slowing in the late 2010s.

Container ships have become so massive that it is difficult to envisage them getting much bigger in future, primarily due to difficulty getting them into ports around the world.

Shipping company MSC has 10 ships on order with a capacity of 24,232 TEU, which will make these new ships the biggest ever. However, although there are ships that can carry as many as 24,000 TEU, no ship this large has ever been filled to capacity.

The highest TEU ever recorded as being carried on a ship stands at 21,710. This record was set by the Ever Ace – capacity 24,000 TEU – as she loaded in Yantian, China and sailed to Rotterdam, Netherlands in August 2021.

It appears unlikely that container ships will get much bigger than they are now. There will certainly not be the exponential growth that we have seen so far, as further increases in size would require major changes to port infrastructure around the world.

The largest container ships are already too large for the Panama canal, and some are very close to being too large for the Suez canal, at which point having such a large ship becomes pointless as any gains from economy of scale are lost in fuel and time costs by having to sail thousands of miles extra around the Cape of Good Hope.

How are containers secured onboard?

Because container ships are more susceptible to rolling motions than pitching motions, containers are always loaded with the shorter ends of the container facing the fore and aft of the ship, as can be seen in the photograph below. This allows for less movement of cargo inside the containers.

Every container ship must carry an official document called a Cargo Securing Manual. This document gives details of the lashing equipment used onboard the ship, expected acceleration forces due to the vessel’s movement, and a spreadsheet for calculating the required number of lashings for different weights and placements of containers.

There are three main methods of securing containers onboard a dedicated container ship: cell guides, twistlocks, and lashing rods.

Cell guides form a part of the structure of the ship and are found both in the ship’s holds as well as above deck. Cell guides are fixed vertical slots which guide containers into place and ensure that they do not move.

Twistlocks are heavy-duty metal locking mechanisms weighing around 5 kilograms each. Twistlocks fit into the corners of any shipping container and allow them to be secured to both the ship’s deck and to another container above and/or below it.

The bottom two rows of containers will also be secured to the deck using lashing rods, which are secured by turnbuckles to maintain tension. Higher up in the stack, some containers may be secured using lashing rods to a platform known as a lashing bridge.

For a visual guide on exactly how containers are secured onboard a ship, check out our video:

It is not only dedicated container ships that can carry shipping containers. Some general cargo ships are also capable of carrying shipping containers above deck.

These ships may either utilise deck space fore and aft of their cargo hatches to secure a small number of containers, or they may have reinforced hatch covers with brackets on top of which containers can be secured.

The technology of container shipping

Onboard, each container has a six-digit code to signify its exact position onboard. Each pair of numbers has a different meaning. For example, a code of 080382 would signify the following:

08 The eighth row back from the bow

03 The second column to starboard of the centreline (even numbers = port, odd = starboard)

82 The second tier above deck level

Because containers are of a standard size, and just about all container ships follow the same design principles, it is easy to see that the containerisation of the shipping industry lends itself to automation.

Automation in a container terminal involves cranes which can be programmed to stack containers in the correct place, robotic vehicles which transport individual containers from the stacks to the quayside, and automatic quayside cranes which move containers between the ship and quay using the six-digit position codes we just learned about.

In 2021 Rizhao Port in Shandong Province, China, became the first port to be entirely automated for loading and unloading all goods – twenty-two overhead cranes at the port are now controlled by just four operators, which increases both efficiency and safety.

Although much of the process can be automated, it still relies on humans planning the operation properly in the first place. This is because no matter how well containers are secured, it is essential that they are loaded in the correct position onboard.

To learn more about how the ultra-large container ship Ever Smart lost over 40 containers due to a combination of heavy weather and improper weight distribution, check out our video:

How to tell how many containers a ship is carrying

If you live in an area where you can see lots of ships, you might find yourself wondering how many containers a ship is carrying. A ship might be carrying thousands of containers, but it’s fairly easy to estimate how many containers a ship is carrying through some simple maths.

To calculate how many containers are above deck, simply count how many rows of containers you can see, how many stacks you can see, how high those stacks are and multiply them together.

To estimate how many containers there are below deck, look at the ship and see how many rows and stacks there are in the middle of the ship. In this instance, the ‘middle’ means the part of the ship which is flat down the sides, between the accommodation and the part where the hull begins to curve toward the bow.

Containers will be stacked at roughly the same height as they are above deck. For example, if you can see that each stack above deck is six containers high, it’s a safe estimate that they are stacked five or six high below deck too. It might not look like it, but remember that there is a huge amount of the ship that you can’t see below the waterline!

Shipping containers – more than just a box

Shipping containers are strong, sturdy structures. They are built to withstand the harsh environment of global shipping, and can easily have a working life of 25 years.

In the last couple of decades, the repurposing of used shipping containers has become increasingly popular.

Shipping containers have been used as homes, restaurants, bars, and office spaces. In developing nations, containers have been used as markets, schools, and even emergency hospitals.